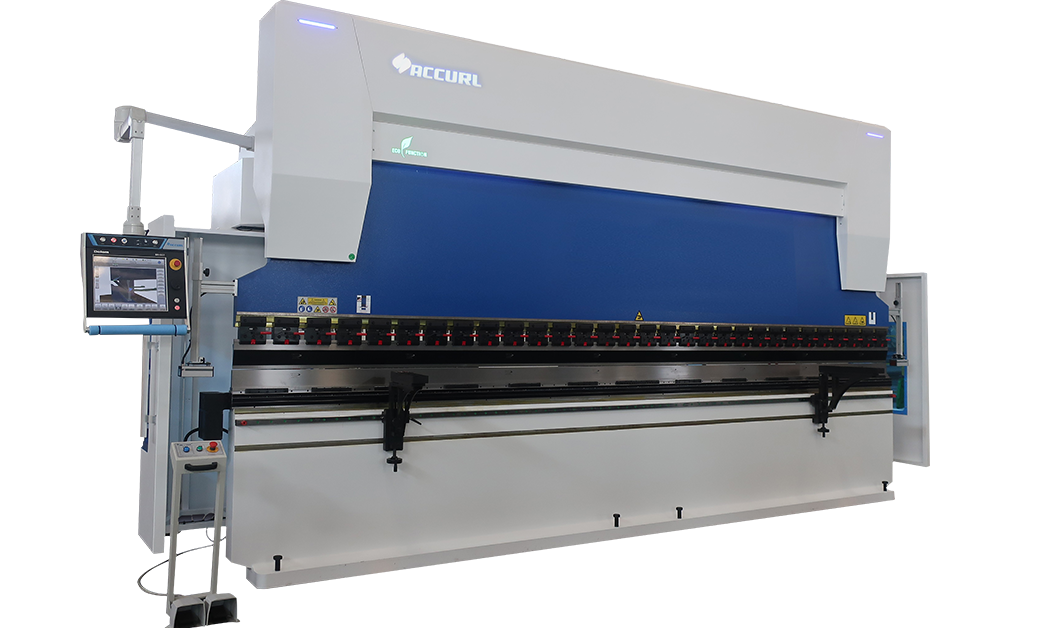

Genius Prime

Faster, More Efficient Than Ever Higher Uptime, Better ROI, And A Leading 3-Year Warranty

- Delem DA58T CNC Control Unit

- DSP Laser Safety System

- CNC Accurl Backgauge System

- Foot Pedals

- Accurl Quick Clamp System

- CNC Clever Crowning

- Front Material Supports

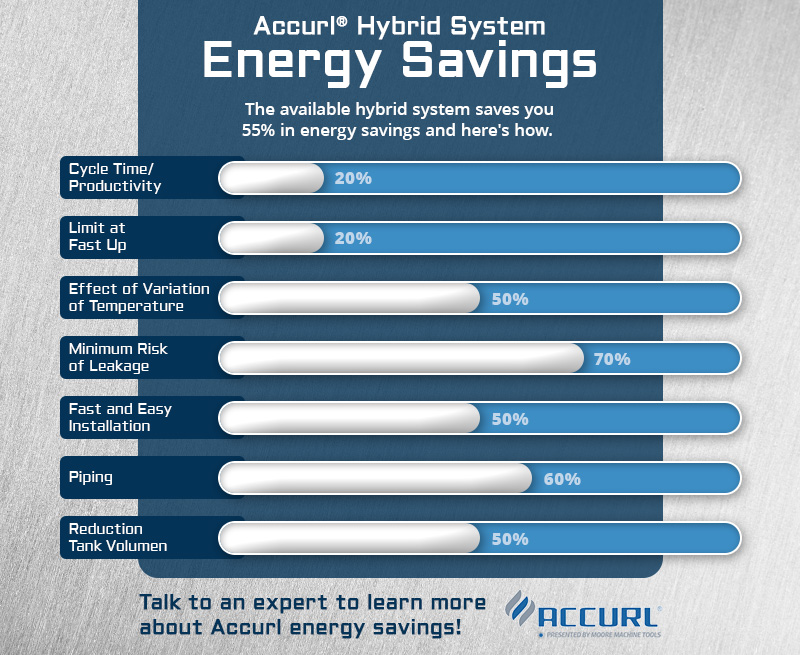

- New Hybrid Eco-function

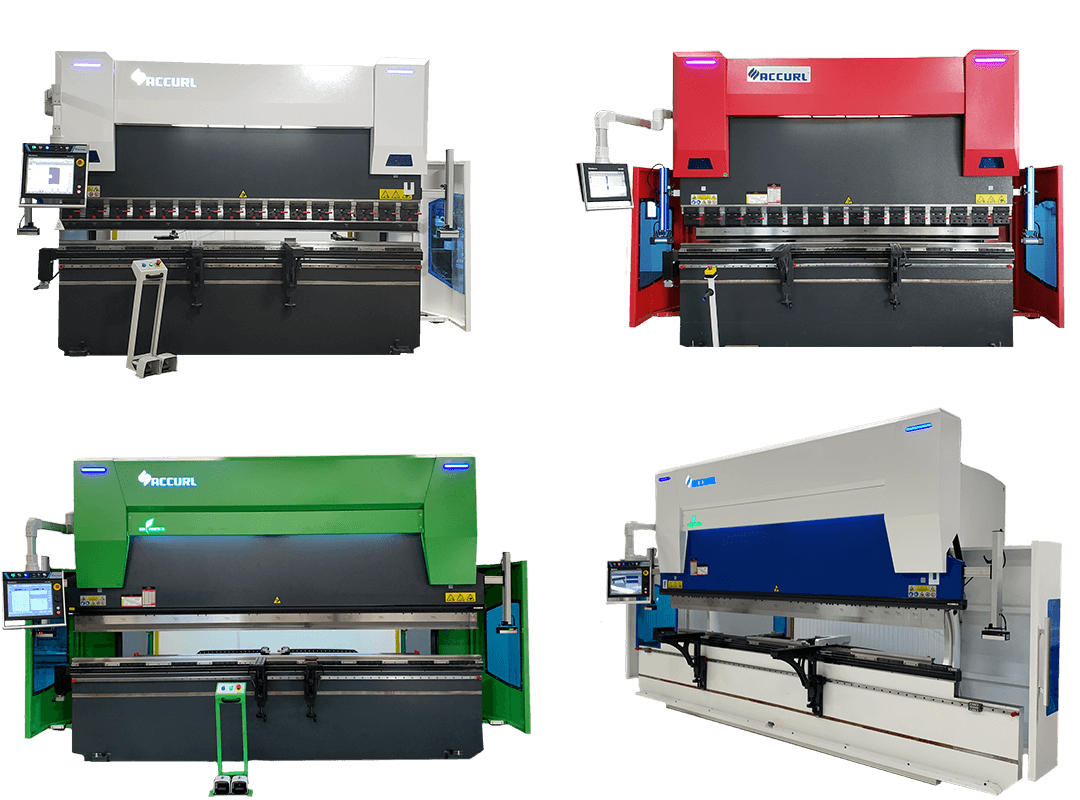

- Comes In Multiple Colors

Genius Prime: The Best 4 Axis Press Brake

The Genius Prime press brake combines the Accurl’s tradition of quality with technology looking to the future. This press brake can increase working speeds, precision or results, while saving on energy costs. What’s more, its user-friendly 2D graphical control unit simulates bending sequences and collision points for results that you can depend on. The Genius Prime has increased the capabilities of the Genius series with the use of hybrid servo driven back gauge, DELEM DA58T controller, embedded DSP Laser Safety System, and more. The Genius Prime press brake delivers on all fronts for a machine tool that has the capabilities to cut costs, increase production, and increase safety.

When you invest in a Accurl Genius Prime press brake, you are guaranteed a reliable piece of machinery that will provide you numerous advantages including cut costs, precision, and repeatable quality results.

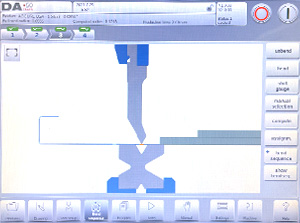

Delem DA58T CNC Control Unit: Powerful Control

Delem is recognized as an industry leader in CNC control panels not only for their efficiency, but also their high-quality design and construction. With a Delem control unit, you can harness the full-power and ability of the Accurl Genius Prime press brake.

- 15” high resolution color TFT (touch screen control)

- 2D graphical touch screen programming mode

- 2D visualisation in simulation and production

- CNC Crowning Control/Bend Sequence Calculation

- Visual tooling library

- Tooling and parts library with 1 gb storage

- Automatically optimizes for best bend sequence and identification with collision detection

Step Previewer

Bar with capability to scroll horizontally to see bending steps

Smart Draft

Generate 2D/3D workpieces through innovative drawing method

Simulation

Ability for real time animation

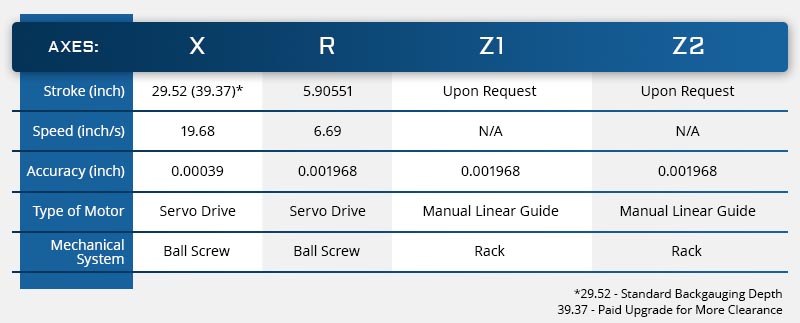

Accurl CNC Backgauge: Built for Precision

All of Accurl’s backgauges for their machines are engineered to be a solid structure. This is a key value proposition for Accurl machines as this provides absolute assurance for the best repetitiveness and a high level of precision.

DSP Safety System

The DSP-AP generates visible laser protection compliant with EN12622 regulations. The beam protects the press brake operator from the danger of being crushed between upper and lower tools and represents the evolution in press brake safety with respect to the inefficient light curtains or obsolete single-beam protections.

This device reduced the mute point — or speed change point — to up to 4 mm from the sheet metal, thus permitting a remarkable saving in the duration of the bending cycle. The amount of time that can be saved by DSP-AP with respect to a conventional system is about 1.2 seconds per bend. Safety features also include blanking for automatic recognition of boxes and profiles with sidewalls.

Supports in the "Safe Release" system were designed to unhook without damages in case of a collision with tools or other objects. Plus, they can be equipped with a CNC-controlled motorized positioning, where the transmitter and receiver are automatically positioned at the correct height depending on tools and working conditions.

Accurl is the industry standard for quality. However, what does that specifically mean?

- DELEM DA-58T CNC control unit with 2D graphics

- 4+1 axis CNC

- Y1, Y2 precision ram positioning

- Standard BGA-2 for X, R, (manual) Z1, Z2-axis ( X=31.5 inch, R= 7.8 inch)

- DELEM offline bending software, Profile TL

- ACCURL PRO CNC motorized wave crowning

- Large trio of value

- Large open height

- Large stroke

- Large throat depth

- HOERBIGER hydraulic valve block, pump and valves

- High Siemens efficiency motor-class IE3

- Hybrid ECO Function for energy-saving drive

- Rear cover: Safety barriers (Category IV)

- Sheet metal frontal supports

- Front and rear lighting

- Industry 4.0 of Productivity Monitor (software version V3.5.3)

- CE Norms: OEM Embedded Lazersafe Systems PCSS A0 + LZS-2 Block Laser (Category IV)

Robust Construction & Custom Colors

Accurl machines are made to last the test of time and the stress of hours upon hours of continuous work. The steel frames of our machines undergo annealing at over 600 degrees to relieve stress.

- Stable base and stiff frame

- Deformation stimulation made by CAE

- Stress points analysis

- High-tech boring machines provide extreme precision parts

Sturdy design for reliable production and usage.

Accurl US machines also come in a variety of color options.

Speak with One of Our Experts

Ready For Industry 4.0: Move Into the Future

The future of the industry is digital, and Accurl is staying ahead of the curve with our ad-hoc software tools, allowing you to extract data and share it easily. Information that you have at your fingertips include bending programming, sensor information, production statistics, and more!

Fully utilize the power of on-demand data.

Press Brake Tooling

A press brake is a machine pressing tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die. Tooling tolerances should be checked each time a punch and die are selected. It is the operator’s responsibility to ensure the tooling fitrs the manufacturer’s specifications, as well as making any adjustments necessary.

Commonly Used Press Brake Dies

In order to extend the service life of the mold, the press brake punch and dies are designed with rounded corners as far as possible. Commonly used press brake dies are as follows:

- Rocker-Type Dies: These dies bend metal by moving up and down, and side to side.

- Gooseneck Dies: Used to clear rims that protrude from workpieces also known as flanges.

- V-Dies: These are used for creating v-shaped bends.

- Acute-Angle Dies: Used to create acute, obtuse, and right angles.

Press Brake Dies Materials

Generally, press brake dies are made of materials like T8 steel, T10 steel, 42CrMo, and Cr12MoV. Cr12Mo is a good material, as the performance can be satisfied. The process performance is also good, but the price can be high. 42CrMo is a high-strength alloy quenched and tempered steel with high strength and strong toughness. It can work under a temperature of -500 degrees Celsius. It mainly required high strength, high toughness, and good wear resistance.

Requirements of Press Brake Tooling

- High Precision - The tools should be manufactured to tolerances within the 0.0004-inch range. This is critical to achieving part accuracy without shimming or other tweaks during setup.

- Segmented Sections - These allow you to build various lengths out of several pre-cut pieces. Small pieces are safer and easier to handle, too.

- Self-Retaining installation - You should be able to load the tools with the ram up. The tool holding system should hold multiple pieces in place until the clamping pressure is applied.

- Self-Seating - As clamping pressure is applied, the punches are mechanically pulled up into position. This eliminates the need to bottom the punch into the die during the setup.

- Front Loading - You should be able to install tools from the front of the machine. This shortens setup time because you no longer need to spend time sliding tools from the end of the press brake. Front-loading eliminates the need for forklifts and overhead cranes.

- Standard Sizes - Common-height tools can reduce the need for machine adjustments when changing jobs. Front support arms, back gauge heights, and safety devices all remain at a common position. Because tools are made to the same heights, you can add off-the-shelf pieces and be sure they will match your existing tools.

Rear Thin Support For Backgauge: Reliable Positioning

With the SPA Thin support system, you can bend thinner sheets and rely on each to always be correctly positioned and guided. This system is installed in the fingers of the back gauge and can be activated with predefined bending. This enables the plate to slide until it lies adjacent to the back gauge. As a result, you can rely on:

- Even the most delicate surfaces are protected by the back supports’ ball sliders and brush.

- Load capacity: 30 kg per support.

CNC Bending Follower Supports AP1 + AP2: An Effective Accessory

These supports are controlled by the CNC and follow and support the sheet during the bending process. They consist of supports on the front of the machine, at the height of the bending line. With this effect accessory, you can experience these advantages:

- Automatic bending follower support.

- AP 1 - AP2 interpolated axes controlled by the CNC machine.

- Bend up to 70 degrees.

- 180 kg. per support load capacity.

- Brush and support shaft dim 350x900 — up to 1200 mm.

WILA® New Standard Pro Clamping System: Increase Productivity

As the market leader, the WILA Tooling System can provide you reliable precision, quality, and flexibility that can ultimately increase your productivity. The changeover process becomes easier and safer with WILA’s state-of-the-art clamp system. Together with the Smart Tool Locator® (STL) you can enjoy ultimate efficiency in changing tools. You will also have:

- A hydraulic power source

- Quick clamping for Europe-style tooling

- Loading with simple push-button

- Maximum load head/shoulders 180 t/m

- Premium is available

WILA® Smart Tool Locator®: For Optimum Press Brake Productivity

LEDs built-in to your machine indicate the right clamping position of your tooling during set-up; in production mode, it also indicates the active tool location. With STL, you can count on increased speed, precision, and flexibility that will provide significant effects to your overall production.

WILA® Pro Crowning and Holders System: Offset Deformations

The WILA system also provides advantages to the use of offset deformations of the beam while bending. This means the angle is constant along the entire plate length for the most precise bending. This means that you experience:

- Tools that are easily reversible.

- Advantages of hydraulic clamping.

- Quick clamping for dies.

Standard

- Tool slot CNC-Deephardened®.

- Drive unit CNC, motor at one end.

- Designed for press brakes with UPB-II hole pattern.

Optional

- Smart Tool Locator® (STL).

- Drive unit CNC; motor completely built-in.

- WILA CNC crowning adjustment.

Accurl & Moore Machine Tools

When you are shopping around for the next machine for your shop, you don’t need to look any further. When you shop with us, you are guaranteed not only a high-quality product, but also a customer service experience that will exceed your expectations. We are industry professionals with years of experience to help you find the right machine for your needs. What’s more, we offer financing options to make having the machine that you need within your budget.

With over 20 years in the industry, we sell and service machines from New York to Alaska to California.

If you want to buy the best product from the best company, then you are in the right place. Contact us today!