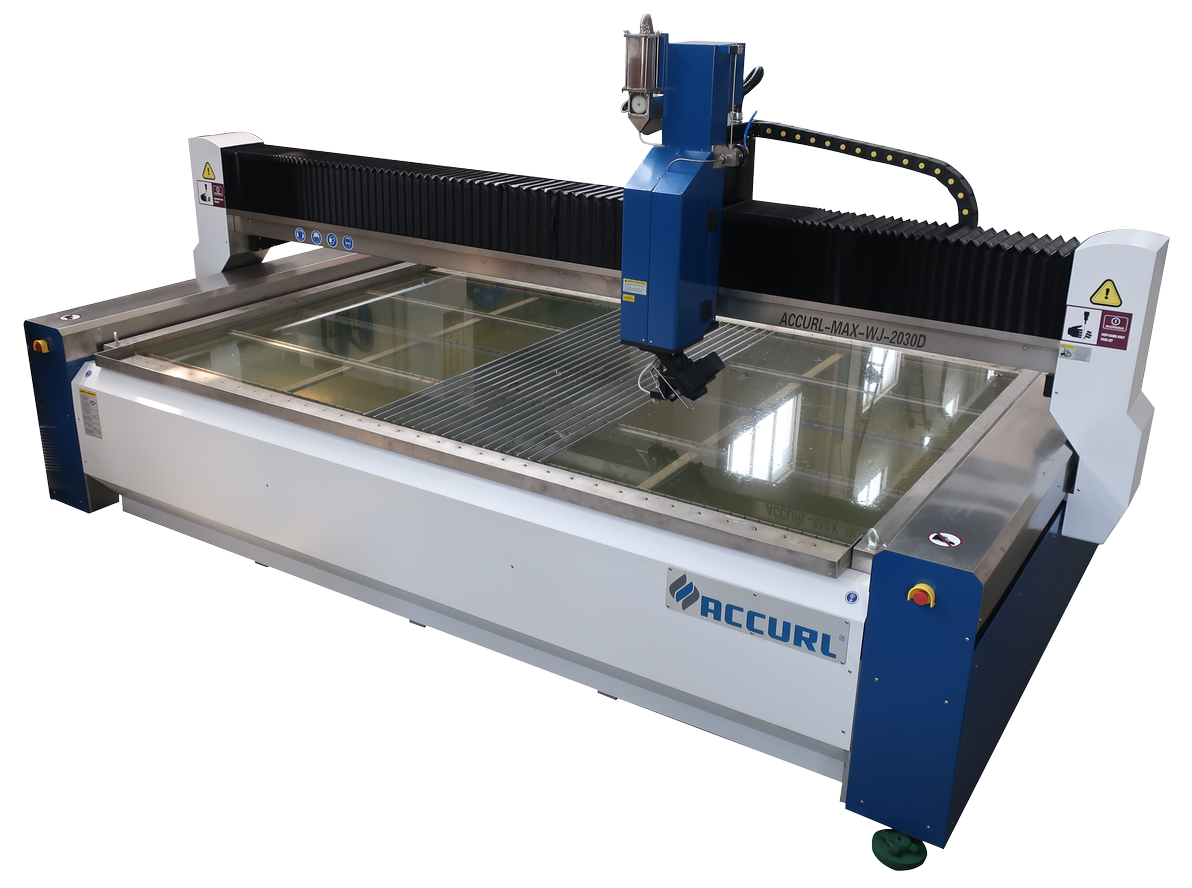

Abrasive Waterjet

Need a precise cutting machine for your manufacturing project? A CNC waterjet cutter offers you more control, scalability, and safety than other machine tools.

Waterjets, or waterjet cutters, are an industrial cutting tool capable of severing a large variety of materials, from wood to metal. They are able to accomplish this by creating a very high pressured “jet” of water, often mixed with another abrasive substance. When industrial materials need to be cut using a method that doesn’t involve heat, a waterjet is a great choice of machine tool.

Most industrial waterjets will be abrasive waterjets, meaning they use a mixture of water and an abrasive substance in order to better cut a material. A pure waterjet is a waterjet that doesn’t use an abrasive mixture and is generally used for purposes of cutting materials like wood or rubber.

Here at Accurl, our CNC abrasive waterjets are able to perform precise manufacturing cuts at scale. If you are looking to increase production with a high-quality machine tool, then Accurl has the solution.

Accurl Waterjets, now offered with Hypertherm line of pumps

Get the same precision and quality cutting you expect from an Accurl waterjet, now with the robust powering of Hypertherm waterjet pumps.

Hypertherm waterjet pumps are proudly made in the USA, plus when you opt for a Hypertherm pump for your Accurl CNC waterjet cutter, you get the combined support of both Hypertherm and Accurl.

Check out some of the high-quality Hypertherm pumps you can use to get the most out of your Accurl CNC waterjet cutter.

Echion 15/30/50 Waterjet Pumps

Looking for the same robust power in a small package? Look no further than Hypertherm’s newest introduction to the waterjet pump lineup: the Echion™ 15, 30, and 50 waterjet pumps.

Perfect for smaller budgets, or just for smaller spaces, the Echion™ line of waterjet pumps still delivers consistent cut quality at optimum cutting speeds. To achieve this, the Echion waterjet pumps come standard with closed‑loop proportional pressure control adjusts for ambient pressure and temperature, oil viscosity, and hydraulic system wear parts. Plus, much like their HyPrecision counterparts, Echion pumps utilize Hypertherm’s Advanced Intensifier Technology to simplify system maintenance — reducing cost and maintaining high production.

For integration in smaller spaces, Echion waterjet pumps can’t be beaten — contact Accurl today to see if Echion pumps are a good solution for your business.

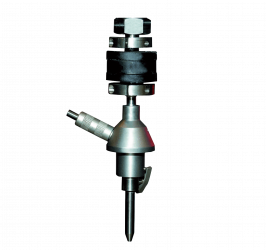

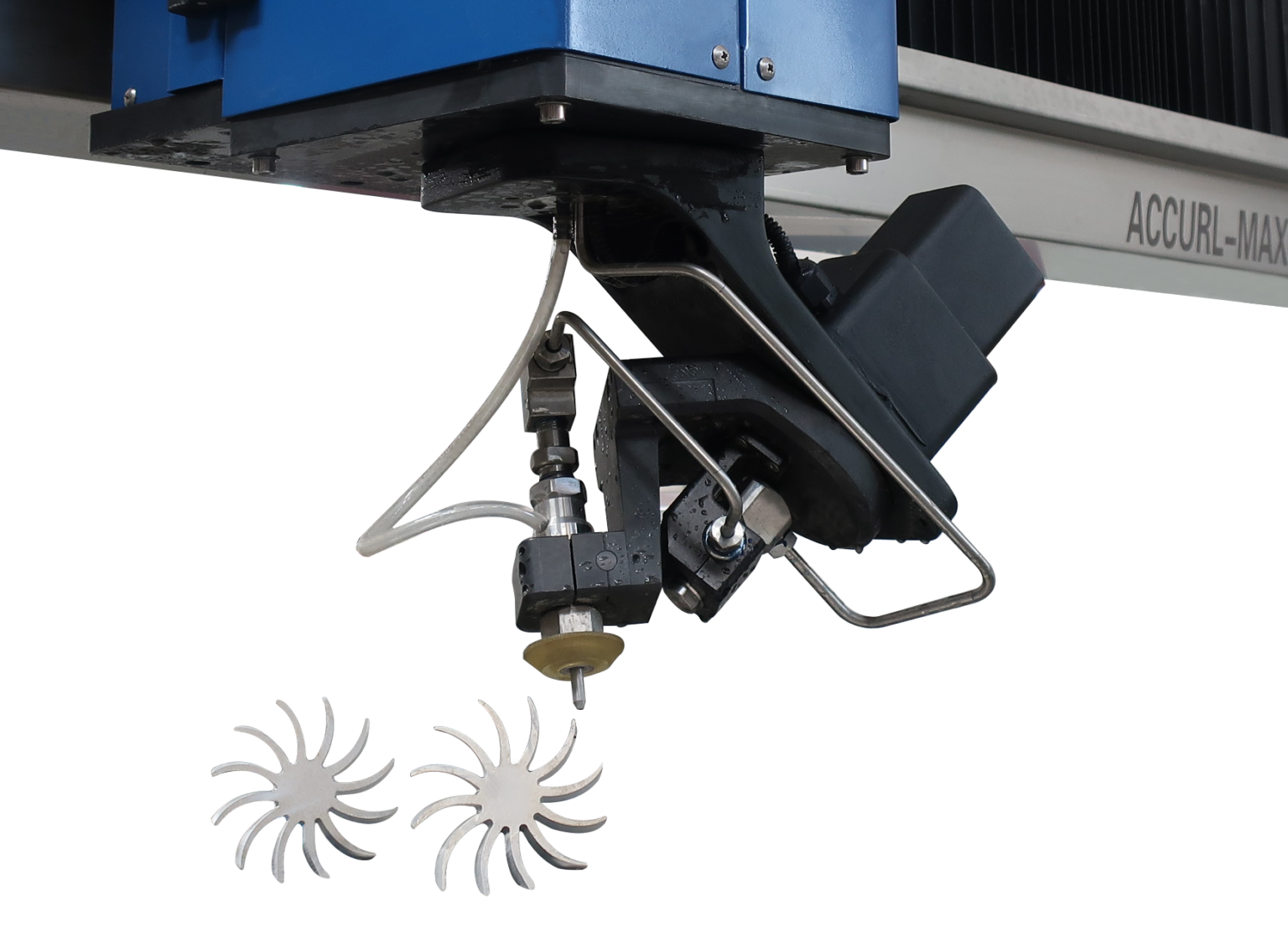

DiaLine Cutting Head

Take your Accurl waterjet cutter to the next level with a DiaLine cutting head. DiaLine cutting heads are at the pinnacle of cutting head technology with a precise design that produces a perfectly aligned cutting stream resulting in a maximum transfer of energy to the workpiece, and less wear and tear on cutting head components.

Furthermore, DiaLine cutting heads feature a diamond orifice which is also backed by an industry-leading 600-hour warranty. You’d be hard-pressed to find a better cutting head for your Accurl CNC waterjet cutter.

Contact us to see if a DiaLine cutting head is right for your waterjet cutter

HyPrecision Predictive Waterjet Pumps

HyPrecision Predictive waterjet pumps feature the latest advancements, building on previous models’ ability to deliver more consistent cut quality while ensuring improved reliability and easy, straightforward service.

Everything about Hypertherm’s latest HyPrecision Predictive waterjet pumps is designed to increase productivity while minimizing maintenance costs. From their Seal Maintenance Technology™ that monitors performance and lets you know when it’s time to change seals to redundant pumps (available on the 50S and 75S pumps) which incorporate a second intensifier, with Hypertherm’s Advanced Intensifier Technology, you can remain productive without worrying about extensive unscheduled maintenance costs.

To learn more about how a HyPrecision Predictive waterjet pump can make your Accurl CNC waterjet cutter more efficient, contact us today!

Accurl is committed to providing the highest quality in CNC machine tool manufacturing, which is why we’re proud to recommend Hypertherm waterjet pumps to help you get the most out of your Accurl waterjet cutter. We’d be happy to explore which Hypertherm products would be best suited for you and your business — fill out the contact form below to get in touch with the Accurl team.

Accurl Quality

We are committed to providing our clients with only the highest quality in CNC machine tool manufacturing. Having been in the manufacturing industry for years, we know just how important machine tools are for the ability to scale with precision. That’s why we work to perfect the latest designs in our waterjet cutters, culminating in products that can handle more accurate manufacturing without sacrificing operator safety.

INCREASED EFFICIENCY

Operators will love the fact that this machine helps to maximize the highest quality results while decreasing per-unit costs.

LESS MAINTENANCE

You can rest easy knowing that you won't constantly be paying for repairs. There is very little maintenance needed for this machine.

IMPROVED SAFETY

Accurl machines exceed safety specifications. The various safety switches and guards offer more protection for the operator.

FAIR PRICING

Looking for a CNC waterjets at a good price point? Well, you're in luck because ACCURL waterjet prices can't be beaten.

Benefits of a Water Jet Cutter

There are essentially three types of automatic cutting machines. The shearing machine uses mechanical strength to shear metal and other materials. This machine is great for many applications, but tends not to be as great for precise cuts. There is the laser cutting machine, which uses heat generated by laser beams to melt and cut through materials. Finally, there are water jet cutters, which use pressure and water (and other liquids) to cut materials. Here are some of the benefits that using a waterjet cutter is associated with.

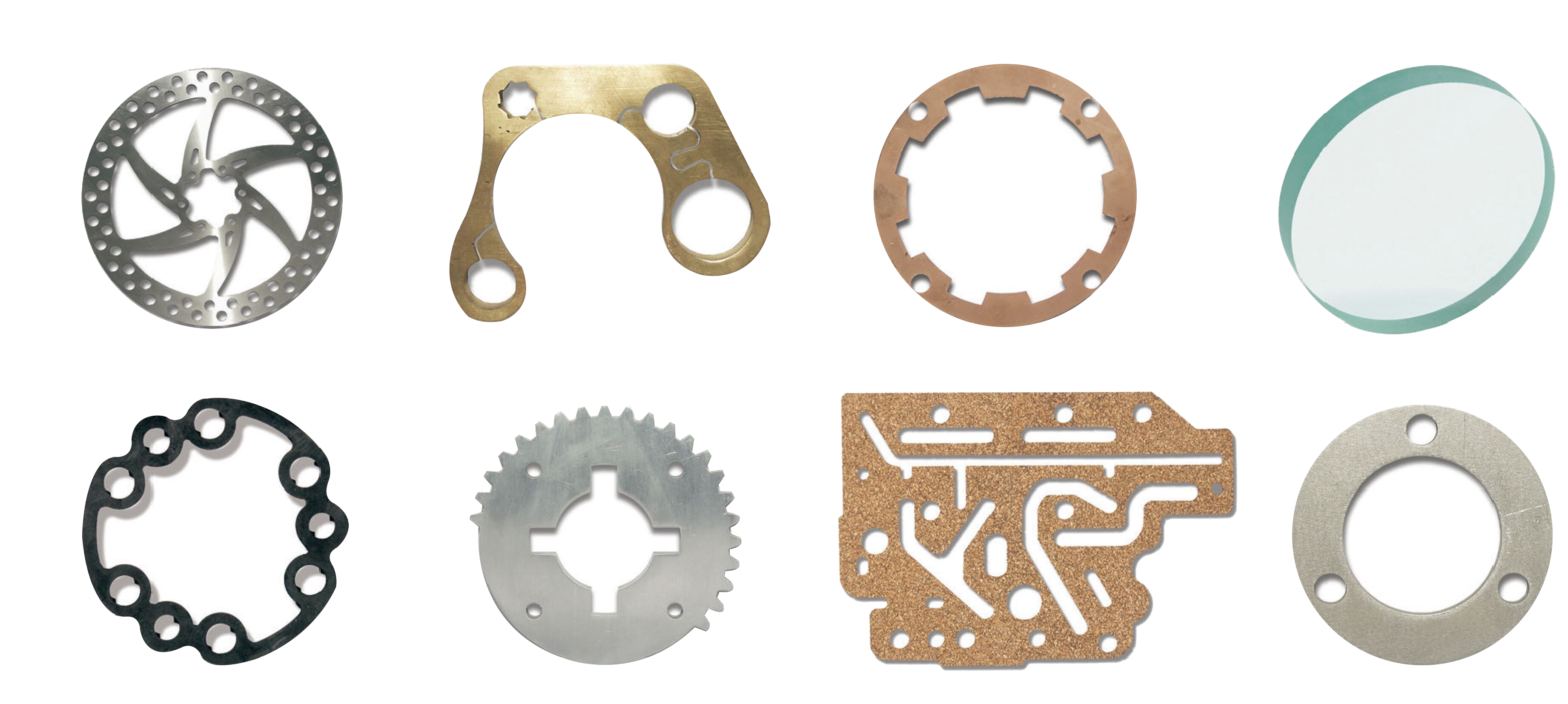

- Waterjet cutters can create precise, complex cuts in any material. Combined with specialized software and 3-D machining heads, even convoluted shapes can be manufactured.

- The kerf, meaning the width of a cut, on a waterjet can be adjusted easily by switching out the nozzle. For abrasive cuts, the kerf can be as narrow as 0.51mm. For non abrasive cuts, the kerf can go down to 0.076mm, which is the width of a human hair.

- Waterjet cutters have no heat-affected zone (HAZ), because they produce no heat. This means that they can cut materials without affecting their inherent chemical structure, allowing them to keep their intrinsic properties. Because of this, bevels, pierce holes, sharp corners, and shapes with minimal inner radii become possible with a waterjet.

- Waterjet cutters' amazing precision allows them to attain accuracy to the level of 0.13mm, and repeatability to the level of 0.025mm.

- Efficient use and design with a waterjet cutter can equate to less scrap metal produced during manufacturing, since uncut parts can be positioned more closely than with traditional cutting machines.

- Operators of waterjets are exposed to fewer hazardous materials from airborne dust particles, fumes, smoke, and other contaminants produced by other machine tools.

- Because waterjet technology has no contact medium (unless the water is recycled), it can actually be used in the meat cutting industry to avoid risk of cross-contamination.

Waterjet Process Characteristics

There are essentially five main process characteristics regarding waterjet cutting:

ONE

The first one is that a high-velocity stream of water (between 30,000-90,000 psi) is produced by a high-pressure pump, and will likely make use of abrasive particles suspended in the water.

TWO

Delicate, hard, and heat-sensitive materials can be cut without harming or changing their intrinsic properties.

THREE

No heat damage is caused on a workpiece surface or material edges.

FOUR

Nozzles are made of either sintered boride or composite tungsten carbide and can be switched to change the kerf.

FIVE

Cuts produce a taper of less than 1 degree, which can be further reduced or eliminated by slowing down the cutting process, or tilting the jet.

ACCURL

5-Axis Waterjet Cutting Machine MAX BP-C Series

ACCURL

MAX BP-C® 3015 WATER JET 50HP

Includes Following Features And Configuration

Flexible

Reliable

Profitable

User Friendly

Standard configuration

The following Smart Components are Optional:

Technological Advantages

Yaskawa Servo Motors & Drives

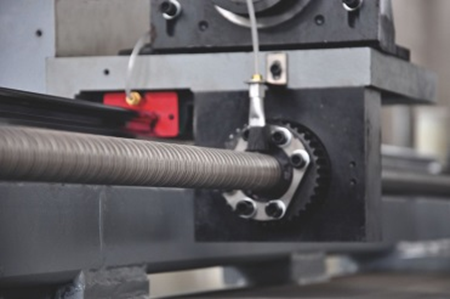

Transmission System

Anti-Collision System • Protection 2.0

Abrasive Backstop System. Cut Control 3.0

Abrasive backstop increases the autonomous operation of the machine. In case the nozzle is blocked, the system prevents water reaching the abrasive dosing system..

Abrasive Regulation • Tci Abrasive 3.0

Technical Specifications.

| Maximum flow |

600 gr/min

| Main voltage |

| 24 VDC |

Control voltage

| 1.10 |

Auto Sullage Removal System 2.0

This unit will condition the incoming water to the intensifier, removing lime from the water. It is highly recommended to install it to ensure filtration and decalcification of the water used for cutting, prolonging the life of all the high-pressure components.

Autonomous Abrasive Feeder-Abraline 3.0

This system is responsible for collecting the abrasive and storing it in its compressed air pressurizing tank. It also pushes the sand to the metering hopper located in the cutting head.

The abrasive transport system consists of:

| Net weight |

| 80 kg |

Length

27.5 in

| (700 mm) |

Width

55 in (1400 mm)

Height

27.5 in (700 mm)

Storage deposit capacity

200 l

Pressurized tank capacity

24 l

Minimum working pressure

| 5 bar |

Maximum working pressure

| 7 bar |

Maximum compressed air consumption

500 l/min

Maximum abrasive flow rate

1.300 gr/min

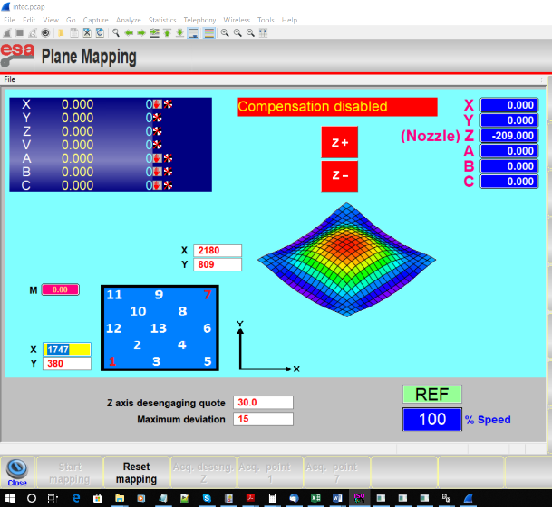

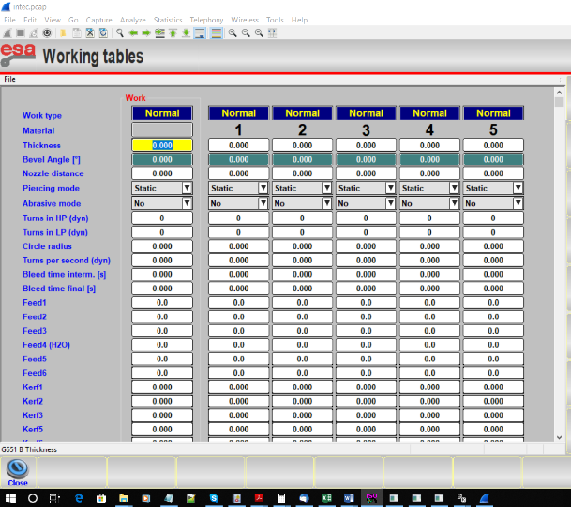

New Esa S660w Cnc With Command Control

CHARACTERSTICS:

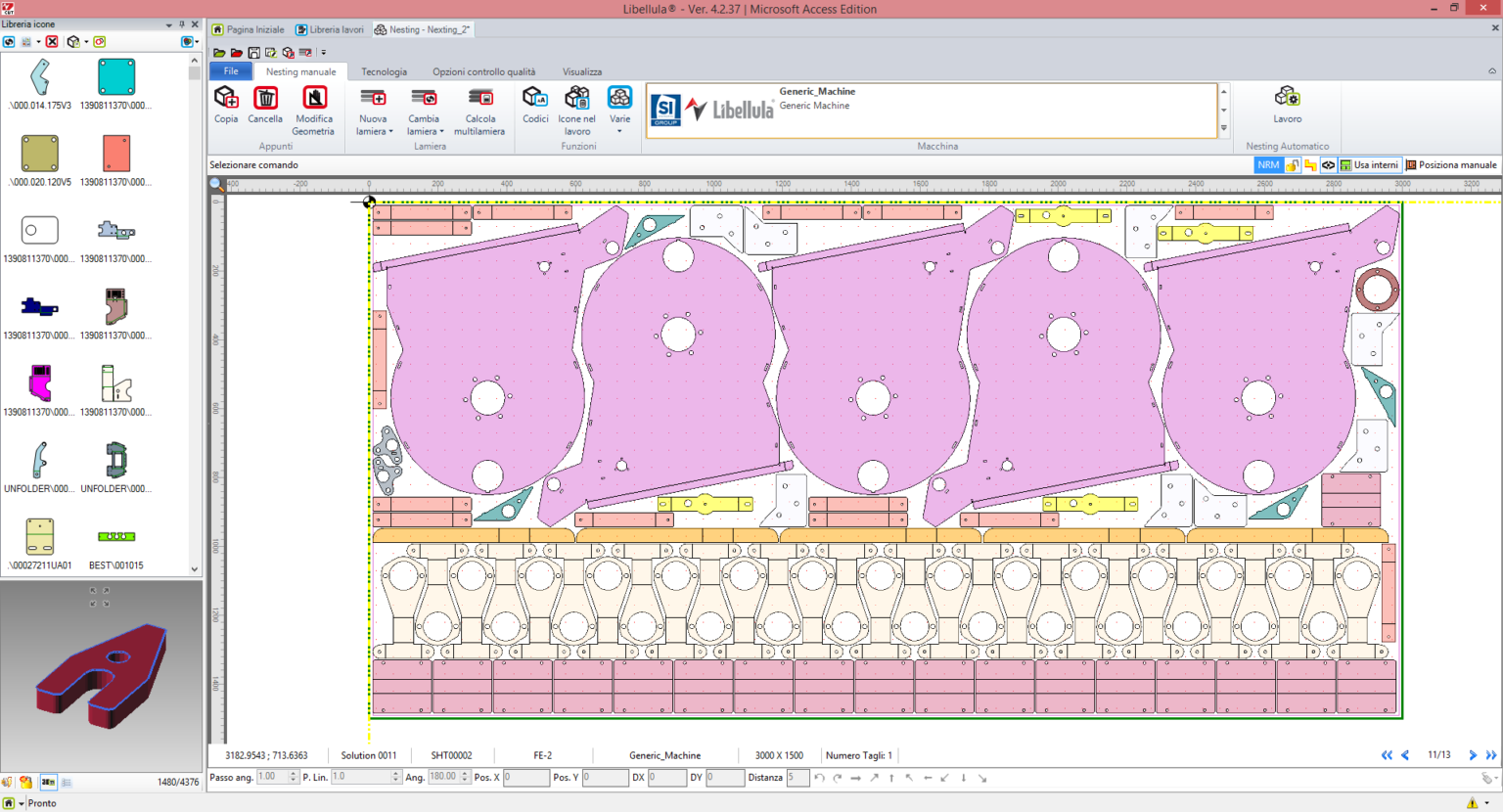

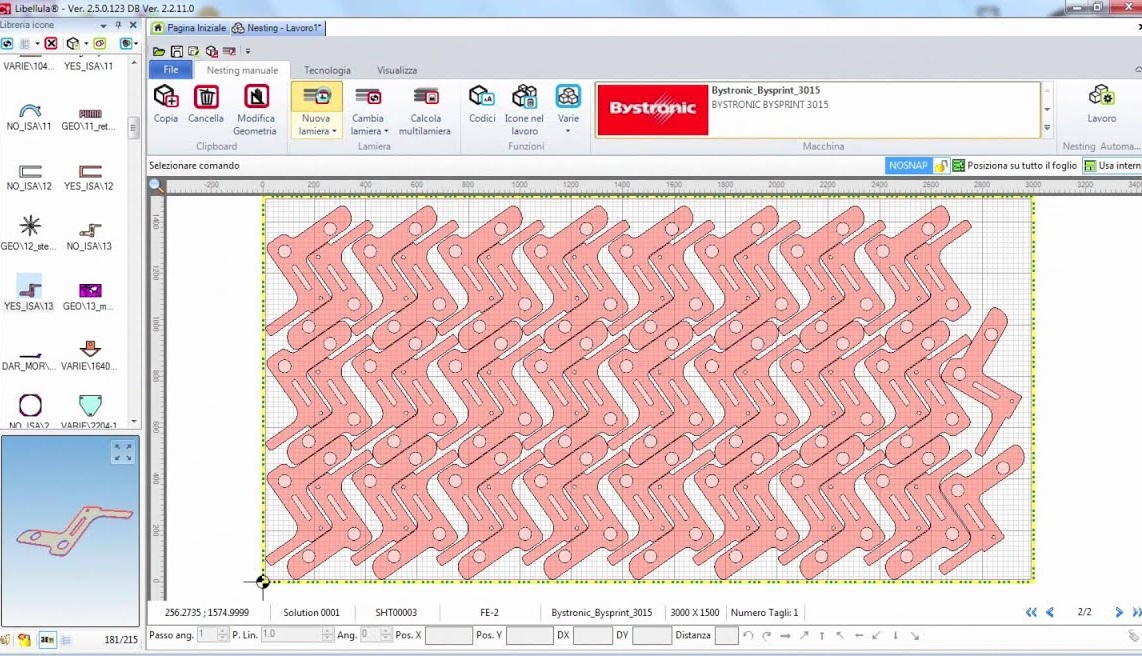

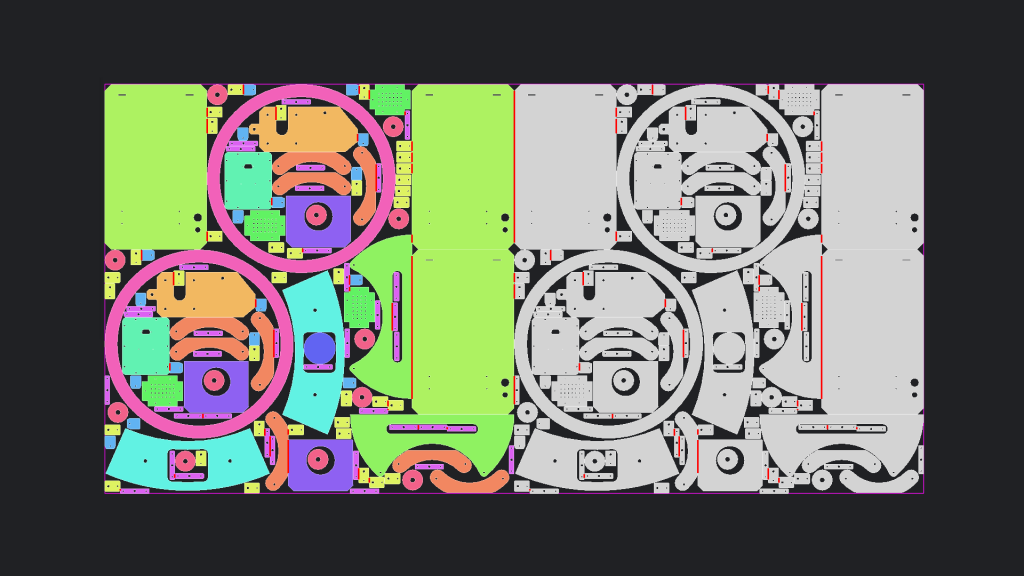

CAD/CAM Software Nesting. Libellula.Cut

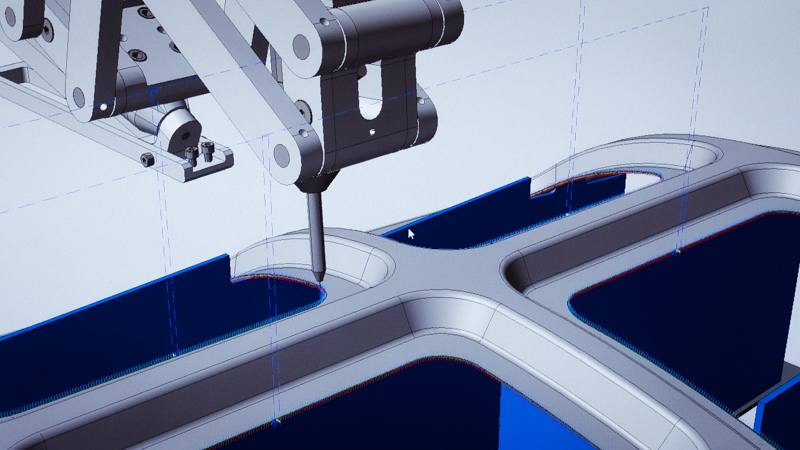

The Max 3d 5-axis Cutting Head 2.0

Advantages:

Note: This level can vary considerably and exceed the set level (85 dB) depending on the cutting conditions and the shape of the pieces when cutting. Therefore, it is necessary that the client / user equips workstations around the machine with the necessary equipment (protective cells, ear protection for operators …) depending on the actual noise

Advantages:

| C axis |

Effective range

| Infinite |

Max positioning speed

| 300 min-1 |

A axis

Effective range

± 60º

Max positioning speed

500 min-1

Clarification on the sound level reached with the use of this cutting head

Hypertherm ® High Pressure Pump •50 Hp

The high-pressure pump is characterized by:

* To cut the maximum thickness, the following conditions must be carried out:

Technical specifications

Nominal power

37 kW / 50 HP

Maximum working pressure

| 4136 bar |

Maximum flow

| 4.1 L/min |

Hydraulic tank capacity

211 L

Pressure accumulator volume

1 L

Water inlet pressure

| 2.4 – 5.5 bar |

Nominal current

72 A

Protection at 400 V / 50 Hz

80 A

Noise level

| 76 dB |

Length x Width Height

66.5x44x59.5 in

(1689x1114x1508mm)

Weight

1438 Kg

CAD/CAM

A modern approach to waterjet cutting.

Fast and accurate

Getting right cut angels while maximizing your feed rate is not as easy as it sounds. A water jet bends, grows, and changes behavior when you give it different parameters to work with. Our strength is to interpret the relationship between the jet and different parameters and turn them into powerful, easy-to-use functions for your convenience.

More parts, less time

Getting more parts out of a sheet while cutting it faster will make you more profitable. Here at Accurl, we think about these things when we develop new features. Our Auto nest has become the most efficient nest on the market, while common cut can nest parts closer together and make a combined cut between them instead of cutting parts individually.

Unparalleled 3D Manufacturing

When your competitors are selling your products, you know you’ve made something extraordinary. In this part of IGEMS CAD/CAM, you can program directly on 3D models, visualize every toolpath, simulate with crash control, and nest your parts. Simply, it’s a 3D environment with automatic and customizable CAM features for as many axes as you need. Contact us today!

Here at Accurl, our goal is to help a certain kind of person and a certain kind of company achieve success: the kind of person that wants to build and build well, and the kind of company that hires those people. If you want to put the tools at your operators’ disposal that will help your company achieve new production goals without sacrificing safety or quality, then Accurl’s machine tools are a great option for you. Our CNC waterjets are just one of the machines that can help your company succeed. For more information about our machine tools, please do not hesitate to give us a call at your earliest convenience. One of our friendly and knowledgeable representatives will be happy to answer any questions that you may have.