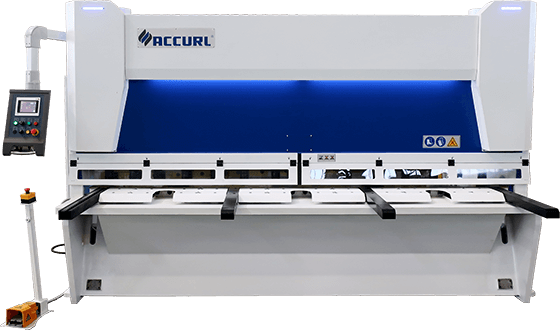

Shearing Machine Tools

Here at Accurl, our goal is to manufacture the most efficient machine tools in the industry. We know how hard manufacturers work to meet their goals all across the world, and that’s why we’re proud to offer them our top-of-the-line machine tools to help them meet their quotas. There are many types of machine tools for a wide array of jobs, but here we want to focus on the shearing equipment that we have for sale.

Accurl Shearing Equipment

We have worked hard to distinguish our brand from other machine tool manufacturers. Our machine tools have helped businesses around the world scale their manufacturing without sacrificing quality in the slightest. This is exactly why we’ve seen so much success, and why we’ve been able to continuously grow and improve our products.

We know that the manufacturing industry is taxing on workers, but that doesn’t stop them. Our shearing equipment not only allows your workers to produce more, but they can do so with the utmost precision and quality, and do it more safely! We encourage any manufacturing business to reach out to us with questions about how our machine tools can help them scale.

Benefits of Buying Accurl

There are a host of machine tool manufacturers out there, but that doesn’t mean that any brand of machine tool you buy will work the same. Accurl focuses their machine tool manufacturing on four pain points that our clients often report, and it’s why we’re associated with the following benefits.

Increased Efficiency

The manufacturing industry isn’t known for slacking, but that doesn’t mean that there isn’t room to grow. Combine hard work with the efficiency of an Accurl machine tool, and manufacturing growth is sure to follow.

Less Maintenance

Machine tools, especially CNC machine tools, tend to require a lot of maintenance. While our Accurl shearing equipment does come with a regular maintenance schedule, it’s designed to require less than the average shearing machine tool.

Imoproved Safety

Production is important, but it should always take second seat to worker safety. This sentiment is echoed in the design of all Accurl’s machine tools, which are made with the operator in mind to minimize any risk of injury on the job.

Fair Pricing

High-end machine tools have a prohibitively high price point for many businesses. That’s something we’re working to change; anybody who wants to put in the hard work should have access to equipment that can help their business grow.

How Shearing Works

A modern shearing machine will have hundreds if not thousands of parts, but in general, a shearing machine uses three parts: a punch (or moving blade), a workpiece, and a die (or fixed blade). The space between the workpiece and die is called the clearance and affects the finish of the cut (burr) as well as the machine tool's energy consumption. The punch pushes the workpiece up against the fixed blade die, which bends the metal with a high degree of precision.