ACCURL NC

Smart Hydraulic Press Brake

ACCURL NC Smart Hydraulic Press Brake

Manufacturing work tends to require hard work and discipline, something true of all the building professions. Like many building professions though, the operator is only part of the equation. The other part? The quality of the machine tools and equipment used to produce. Here at Accurl, we produce only the highest quality machine tools for our clients, and our press brakes are no exception.

Why Accurl?

Accurl has been on the cutting edge of the CNC machine tool manufacturing industry for years. Their machine tools focus on increasing efficiency without sacrificing precision or operator safety. This commitment to quality manufacturing is why Accurl is known around the world as one of the top CNC press brake manufacturers.

Why Choose the ACCURL NC Smart Hydraulic Press Brake?

This sheet metal NC hydraulic press brake is certainly built using top-grade technology to ensure long-term usage, no matter how brutal the job might be. Professionals within the sheet metal industry find this machinery to demonstrate supreme dexterity—and is the simple solution for almost all metalworking jobs.

There is no doubt that you’ll be able to get precision just where you need it the most in any metal fabrication job. This one might present as simple, but it is extremely powerful. The body design of this machine is fully automated with continuous operation modes that make the work easier for the operator. Safety is also a big priority in the design of this ergonomic friendly machine. In fact, due to the safety barrier and the electrical interlock — the operator couldn’t ask for a higher level of operational safety.

So, when you’re looking for a powerful sheet metal machine that can practically take on any metal bending job safely, effectively and cost-efficiently, there’s no need to look further than right here. Request a quote today!

Why Contact Accurl USA?

☑️ US-Based Customer Service, in Utah

☑️ Whatever Your Industry, We Have Experts Who Understand It

☑️ We Don't Just Sell Machines, We Provide Solutions

The Right Tools For The Right Solution. Every Time.

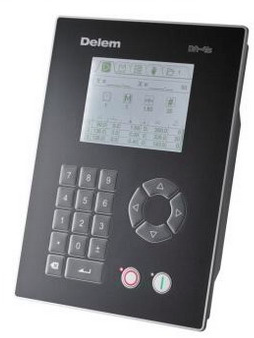

DELEM DA41s CONTROL SYSTEM FOR THE HYDRAULIC PRESS BRAKE:

- Bright 4.7” monochrome LCD display

- Beam stop control

- Back gauge control

- Angle programming

- Tool programming

- Retract function

- Up to 100 programs

- Up to 25 bends per program

- Panel-based housing

- Servo control / inverter /2-speed AC control

- High-quality foil cover with integrated membrane switches